The compressor release setting is a crucial component in regulating the pressure of compressed air. It determines the point at which the compressor stops building pressure and releases the excess air to prevent damage.

The correct setting ensures efficient operation and prolongs the compressor’s lifespan. Understanding the importance of compressor release settings is crucial for anyone using a compressed air system. Compressed air is used in a wide range of industries, from automotive to manufacturing to construction, and the correct compressor settings can make all the difference to the effectiveness and longevity of the system.

This article delves into the factors that determine the appropriate settings, highlighting the benefits of accuracy in pressure regulation. We will also discuss the types of compressors that may require different release settings and the repercussions of getting it wrong. By the end of this article, you will have a thorough understanding of the compressor release setting and how to optimize it for your specific application.

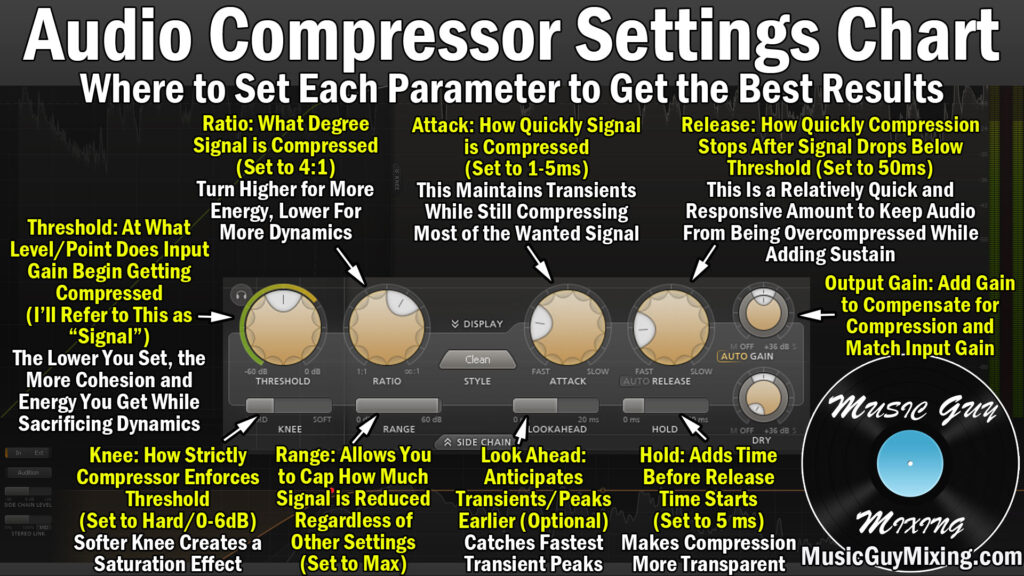

Credit: www.musicguymixing.com

Types Of Compressor Release Settings

The compressor release setting is a vital feature in compressors that can greatly affect audio quality. There are various types of compressor release settings available, including fast, medium, and slow. The choice of setting largely depends on the type of audio being recorded and personal preference.

Compressor release setting is an important aspect of audio mixing and audio engineering. It basically refers to the time it takes for a compressor to stop compressing after the audio signal drops below the threshold level. There are two types of compressor release settings: positive and negative.

Positive

Positive compressor release setting is also known as slow compressor release. It is the amount of time it takes for the compressor to stop compressing after the audio signal drops below the threshold level. Positive release settings are used when trying to bring out the sustain of an instrument or vocal. This setting is ideal for recordings with a lot of dynamic range and for instruments or vocals with a lot of sustain.

Negative

Negative compressor release setting is also known as fast compressor release. It is the amount of time it takes for the compressor to stop compressing after the audio signal drops below the threshold level. The negative release setting is ideal for recordings that need to sound punchy and in-your-face. It’s perfect for instruments with sharp transients, such as drums and percussion. The negative release setting helps to preserve the transients of the signal, which ensures that the overall sound is not affected by the compressor. Table: Comparison between Positive and Negative Compressor Release Setting | Positive Release Setting| Negative Release Setting | |————————|————————–| | Slow compressor release| Fast compressor release | | Ideal for recordings with a lot of dynamic range and sustain | Ideal for recordings that need to sound punchy and in-your-face | | Brings out the sustain of instruments or vocals | Preserves the transients of the signal | | Best for instruments or vocals with a lot of sustain | Perfect for instruments with sharp transients like drums and percussion | In conclusion, understanding and experimenting with positive and negative compressor release settings can take your audio mixing and audio engineering to a whole new level. Choosing the right compressor release setting can make a huge difference in the overall sound quality of your recordings. So, play around with different compressor release settings to take your audio production to the next level.

Credit: www.greatchurchsound.com

Factors That Affect Compressor Release Settings

The compressor release setting is crucial for efficient and safe operation of compressors. Several factors affect the compressor release setting, such as the type of refrigerant used, ambient temperatures, and system operating conditions. Proper consideration of these factors ensures optimal compressor performance.

Compressor release settings are a crucial element to ensure the proper working of refrigeration systems. The compressor release settings are often set based on the type of refrigerant, compressor size, and ambient temperature. The release settings help to maintain the pressure in the system. Inconsistent settings can lead to several problems, leading to damage to the compressor. In this section, we will discuss the factors that affect compressor release settings.

Ambient Temperature

Ambient temperature plays an important role in determining the compressor release setting. Hot temperatures require higher release settings than cold temperatures. The compressor release valve helps relieve excess pressure build-up in the discharge line. If the compressor release valve is set too high, it can lead to compressor failure due to high discharge pressures. Similarly, setting the valve too low can lead to low compression ratios, resulting in poor system performance.

Compressor Size

The size of the compressor determines the amount of refrigerant that flows in the system and the workload it can handle. Large compressors require higher release settings to maintain proper pressure levels. Small compressors, on the other hand, require lower release settings. The release settings are adjusted, keeping in view the specific needs of the refrigeration system and the compressor size.

Type Of Refrigerant

The type of refrigerant used in the system determines the required compressor release setting. The release settings for a system using a high-pressure refrigerant such as R22 will be different from those using low-pressure refrigerants such as R134a. The required pressure levels for each refrigerant type are different, and the release settings must be adjusted accordingly. In conclusion, the proper compressor release setting is critical for maintaining optimal performance, reducing energy consumption, and preventing compressor failure. Ambient temperature, compressor size, and the type of refrigerant are the three primary factors that determine the compressor release setting. It is vital to adjust these settings consistently and accurately to ensure the system works efficiently and avoid costly repairs.

Consequences Of Incorrect Compressor Release Settings

Compressor release settings are critical to the efficient functioning of refrigeration systems. Any mistakes in setting release pressure can have negative consequences on the compressor and the entire system. Below are some of the possible consequences of incorrect compressor release settings:

Short Cycling

Short cycling is a common consequence of incorrect compressor release settings. This occurs when the compressor turns on and off too frequently. Short cycling causes wear and tear on the compressor and can lead to system failure. Additionally, short cycling affects the performance and efficiency of the entire refrigeration system.

Uneven Cooling

Another consequence of incorrect compressor release setting is uneven cooling. If the refrigerator is not cooling uniformly, it can be a sign that the compressor release settings are incorrect. When the compressor is not releasing at the right time or pressure, it affects the refrigerant flow, and some parts of the refrigerator may not cool as efficiently as others.

Compressor Failure

Compressor failure can happen due to incorrect compressor release settings. When the release pressure is too low, the compressor may not turn off, causing it to overheat and eventually fail. On the other hand, when the release pressure is too high, it can cause the compressor to work harder, leading to excessive wear and tear and eventual failure.

Therefore, it is crucial to ensure that the compressor release settings are appropriate for the refrigeration system to work efficiently and avoid potential failures.

Credit: theproaudiofiles.com

How To Determine The Correct Compressor Release Setting

Compressor release setting is a crucial aspect of compressor control. It allows the compressor to release pressure when the system needs it, in turn preventing any damages to the compressed air system. Determining the appropriate compressor release setting is vital to ensure optimal system performance and efficiency. Here are some tips to help you determine the correct compressor release setting.

Consult Manufacturer’s Guidelines

One of the quickest methods to determine the correct compressor release setting is by consulting the manufacturer’s guidelines. Manufacturer’s instructions contain all the information you need to get the best performance from your air compressor. Consult the manual or contact the manufacturer’s support staff to know the compressor’s ideal release setting as per its capacity and capabilities. Keep in mind that every compressor model has unique characteristics, and release settings will vary according to those characteristics.

Consider External Factors

External factors that affect the compressor release setting includes environmental factors like temperature, altitude, and humidity, as well as the configuration of the compressed air system. The pressure requirements of your compressed air system will dictate the compressor release setting. Thus, consider external factors such as ambient temperature, the number of air leaks in the system, or the specific air tools’ requirements. Also, you can adjust the compressor’s release setting to match the pressure setting and recommend valves based on the pneumatic tools in daily use.

Determining the correct compressor release setting can help improve system performance, lower maintenance, and repair costs.

Adjusting The Compressor Release Setting

Adjusting the compressor release setting is key to enhancing the sound quality and dynamics of your music. This simple process involves modifying the release time of the compressor to match the rhythm of the song. By doing so, you can achieve a more polished and professional sound.

Adjusting the Compressor Release Setting is a crucial task for any sound engineer. It ensures that the compressor is working effectively and producing high-quality sound output. The release setting controls how fast the compressor returns to its normal state after it has been activated. This setting helps to prevent distortion and maintain a consistent volume level. In this article, we’ll go through a step-by-step process of how to adjust the compressor release setting.

Tools Required

Before we begin, it’s essential to have the right tools in hand. Here are the tools you will need:

- Screwdriver

- Audio Compression Unit

- Computer/Laptop

Step-by-step Process

Adjusting the Compressor Release Setting is a relatively straightforward process, but you need to follow some specific steps to get the best results. Here is a step-by-step guide:

- Turn off the Audio Compression Unit

- Locate the release setting knob

- Turn the knob counterclockwise to increase the release time

- Turn the knob clockwise to decrease the release time

- Turn on the Audio Compression Unit

- Check the sound output for any distortion or inconsistencies

- Repeat the process until you achieve the desired sound output

It’s essential to note that you need to adjust the release setting while playing a piece of music or audio recording. This approach will help you fine-tune the compressor’s release time to match the audio output. In conclusion, adjusting the compressor release setting is an essential task that every sound engineer needs to master for producing high-quality sound output. By following the above step-by-step guide and using the right tools, you should be able to achieve the desired sound output and minimize distortion.

Frequently Asked Questions Of Compressor Release Setting

What Is The Best Compressor Release Time?

The best compressor release time varies depending on the specific audio source and desired effect. Generally, shorter release times are recommended for percussive sounds and longer release times are better for sustained sounds like vocals or strings. Ultimately, experimentation and listening are crucial in determining the ideal release time for a given track.

What Does Release On Compressor Do?

The release on a compressor is a valve that allows for the safe and controlled release of compressed air or gas. This function is important for maintenance and safety purposes, as it allows operators to depressurize the system before performing any maintenance or repairs.

What Is The Release Knob On A Compressor?

The release knob on a compressor controls the time it takes for the compressor to stop compressing once the audio signal falls back below the threshold. A longer release time allows for a more natural sound, while a shorter release time provides a more aggressive sound.

What Should The Attack And Release Settings Be For Mastering Compressor?

For mastering compressor, the attack settings should be fast for controlling peaks and the release settings should be moderate for overall volume leveling. It ultimately depends on the specific material being mastered and personal preference. Experimentation and careful listening are crucial in finding the optimal settings.

Conclusion

Setting the right compressor release value is a crucial step towards efficient compressor performance and extended equipment lifespan. In this blog post, we explored the various factors that influence the compressor release setting and how to determine the optimal release value.

By following the guidelines shared in this post, you can ensure that your compressor runs smoothly and safely while delivering optimal results. Remember to regularly monitor and adjust the release setting to keep your compressor functioning at peak performance. Thanks for reading!