Knee setting on a compressor is the process of adjusting the pressure switch to prevent the machine from overworking. With this setting, the compressor will automatically turn on and off at the desired pressure range.

When it comes to the world of pneumatic tools, compressors play a crucial role. These machines convert power into potential energy, allowing tools such as nail guns and paint sprayers to operate. However, if the compressor is not set up correctly, it may lead to ineffective performance.

This is where knee setting on a compressor comes into play. Essentially, the knee setting is adjusting the pressure switch to match the desired pressure range. This ensures that the compressor does not overwork, saving on energy costs and increasing the lifespan of the machine. We will discuss in detail the process of knee setting on a compressor.

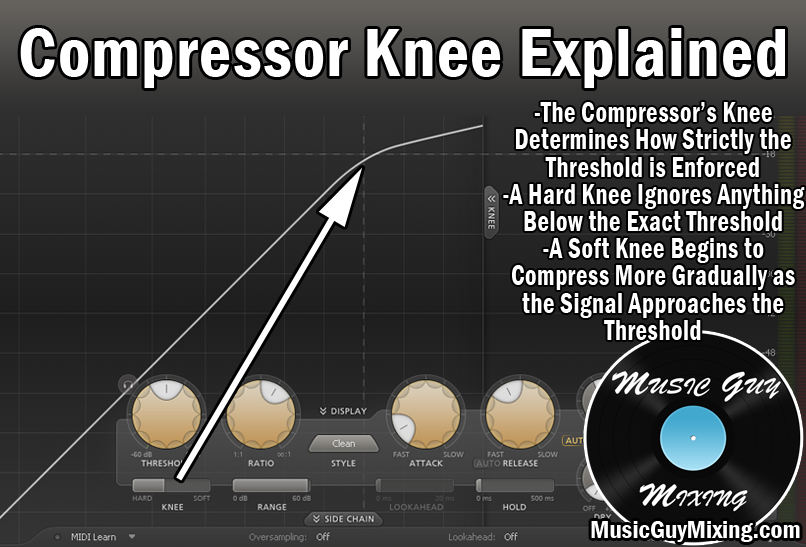

Credit: www.musicguymixing.com

What Is Knee Setting?

Knee setting on a compressor is the process of adjusting the air compressor’s pressure switch to control the cut-in and cut-out pressure of the compressor’s motor. This is important to ensure the compressor operates efficiently and safely, without risking damage to the system or injury to those working with it.

Knee setting is an important feature in air compressors and it is used to regulate the air output of the compressor. It involves setting the pressure at which the compressor will stop delivering air, and it is usually set lower than the maximum operating pressure.

Explanation

Knee setting is the point at which the compressor stops delivering air. The pressure is set at a specific point, which is usually below the maximum operating pressure. This is done to prevent the compressor from reaching its maximum pressure, which can cause damage to the compressor and the equipment it powers. Knee setting is adjustable and can be set to any pressure level within the compressor’s range.

Importance

Knee setting is an important feature to ensure optimal performance and efficiency of the air compressor. Setting the knee pressure will prevent the compressor from working at full capacity, which can lead to overheating, wear and tear, and eventual breakdown. Additionally, knee setting can prevent system leaks and reduce the amount of energy required for the compressor to maintain consistent pressure. By keeping the pressure level within the set range, the compressor runs at a more consistent level, which can also extend the life of the equipment. In summary, knee setting is an essential feature in air compressors that regulates the air output to ensure optimal performance, efficiency, and longevity of the equipment. It is a feature that needs to be set correctly to prevent damage to the compressor and its associated equipment.

How To Set Knee On A Compressor?

One of the important steps in setting up a compressor is adjusting the knee setting. To do this, start by turning off the compressor and checking the manufacturer’s instructions. Then, adjust the knee to the desired pressure range, making sure not to exceed the compressor’s maximum capacity.

Adjustment Procedure

To set the knee on a compressor, you need to take the following steps:

- First, switch off the compressor and unplug the power cord from the socket to avoid electric shock.

- Then, remove the belt guard cover to expose the crankshaft and belt drive system.

- Locate the knee, which is a lever mounted on the crankshaft, parallel to the compressor motor.

- Loosen the knee lock nut and adjust the knee’s position on the crankshaft by moving it up or down to set the desired pressure limit.

- Now, tighten the lock nut back to secure the knee’s position on the crankshaft

- Once done, test the compressor by turning it on and checking for the desired pressure limit.

Tips To Remember

While setting the knee on a compressor, the following tips will help you:

- Make sure to read the manufacturer’s instructions and specifications before attempting to adjust the knee.

- Keep your hands and tools away from the belt drive system to avoid any injuries.

- Use protective gear such as gloves and goggles to avoid any accidents.

- Always unplug the power cord from the socket while adjusting any components inside the compressor.

- Regularly check and maintain the compressor’s belt drive system, knee, and other components to ensure their smooth functioning.

By following the above steps and tips, you can easily set the knee on a compressor, and ensure that it operates safely and efficiently. Remember to be cautious while handling any components inside the compressor and do not attempt to modify or adjust them beyond their specified limits.

Types Of Knee

Knee setting on a compressor is an essential feature that compressors must-have. It allows the compressor to maintain a consistent and stable flow of air. Knee settings help to regulate the compressor’s intake and exhaust valves, which directly impact the performance of the compressor. There are three main types of knee settings: fixed knee, adjustable knee, and swing knee.

Fixed Knee

A fixed knee setting on a compressor is a basic type of knee setting that maintains a constant airflow. The fixed knee setting is not adjustable for changing the compressed air requirements of the application. Thus, it can lead to wasted energy when compressed air demand is low, leading to increased power consumption. The fixed knee setting is suitable for applications that require a consistent air supply and do not have varying air demand.

Adjustable Knee

As the name suggests, the adjustable knee setting lets you adjust the knee point based on the compressed air demand. The knee point is the pressure point where the compressor adjusts its output, with the demand. The adjustable knee setting allows you to set the required pressure range at the knee, ensuring the compressor delivers compressed air accordingly. This feature ensures energy efficiency, as the compressor only supplies the required compressed air, depending on the needs of the application.

Swing Knee

A swing knee setting is the most advanced knee setting on a compressor as it allows you to adjust the knee point precisely depending on the compressed air demand. This feature allows you to maintain the required air pressure in your application with a lower amount of compressed air. The swing knee setting is ideal for applications that have varying air demand and require precise air pressure control.

Credit: theproaudiofiles.com

Factors To Consider While Setting Knee

Knee setting refers to the point at which the compressor shuts off after reaching a particular pressure. This setting is crucial as it determines the life of the compressor, energy consumption and the output of the compressor. There are different factors to consider to get the right knee setting on a compressor:

Pressure Range

The first factor to consider while setting knee is the appropriate pressure range for your compressor. Each compressor is designed for a specific pressure range, and you should check the manufacturer’s manual for the recommended values. Notably, knee settings should range between 70% and 90% of the compressor cut-out pressure.

Material Type

The material type should also influence the knee setting for a compressor. Different materials require different pressure levels to achieve maximum efficiency. You do not want to go beyond the safe pressure level for your material; else, you risk damage to your equipment or inconsistency in output. Check your material specifications for the recommended pressure level and adjust the knee setting according to that.

Required Output

The required output should play a significant role in determining the knee setting. You must ensure you set the knee according to the output requirements to prevent overloading the compressor. A high output requirement translates to a higher knee setting, while a lower output requirement means you can set the knee at a lower pressure. Always ensure you measure your output accurately to set the knee setting correctly.

Setting knee compressors is essential to ensure high-efficiency operations and avoid damaging your compressors. Failure to set your compressors to the right knee point can lead to reduced productivity and increased wear and tear. By considering factors like pressure range, material type and required output, you can adjust your knee setting optimally.

Common Mistakes While Setting Knee

When it comes to knee setting on a compressor, there are some common mistakes that people tend to make. Some of these include not aligning the knee properly, using incorrect settings, or applying too much pressure. It’s important to take the time to properly set your knee to ensure optimal performance and avoid injury.

Setting the knee on a compressor is an essential step before operating it. The knee helps in regulating the pressure and ensures that the compressor runs efficiently. However, there are some common mistakes that people make while setting the knee on a compressor. These mistakes can result in damage to the equipment, safety issues, and reduced efficiency. Here are some of the common mistakes people make while setting the knee on a compressor:

Over Tightening

One of the most common mistakes people make while setting the knee on a compressor is over-tightening. Over-tightening can damage the equipment, lead to leaks, and result in reduced efficiency. It’s important to remember that the knee should be snug and not overly tightened. Tightening the knee too much can result in the compression ring getting deformed, or the seat getting damaged. Therefore, it’s important to read the manufacturer’s recommendations and follow them carefully.

Under Tightening

Another mistake that people make while setting the knee on a compressor is under-tightening. An under-tightened knee can result in leaks, which can lead to safety issues, equipment damage, and reduced efficiency. It’s important to make sure that the knee is tightened enough to prevent leaks but not excessively. An under-tightened knee can also cause the compressor to run at pressures below the required specifications.

Not Checking Before Use

One of the most common mistakes people make is not checking the knee before use. It’s important to check the knee before operating the compressor, as it ensures that it’s properly set and functioning correctly. It’s recommended that you check the knee before use each time, especially if you haven’t used the compressor in a while. A quick check can prevent potential issues that can cause delays, safety concerns, and reduced productivity. In conclusion, setting the knee on a compressor requires careful attention to detail to prevent common mistakes. Over-tightening, under-tightening, and not checking the knee before use are some of the most common mistakes people make while setting the knee. By avoiding these mistakes, you can ensure the compressor runs safely, efficiently, and without any issues.

Credit: www.mixinglessons.com

Frequently Asked Questions On Knee Setting On A Compressor

What Is The Knee Control On A Compressor?

The knee control on a compressor is a feature that allows the compressor to operate at a range of pressures. When you adjust the knee control, it sets the range for the compressor’s output pressure. This means it will regulate air flow according to the level of demand, making it more efficient.

What Is The Knee Ratio For Compressor?

The knee ratio for compressor refers to the ratio of the minimum discharge pressure to the maximum allowable working pressure. It is used to determine the operating limits of the compressor and ensure that it operates within safe parameters.

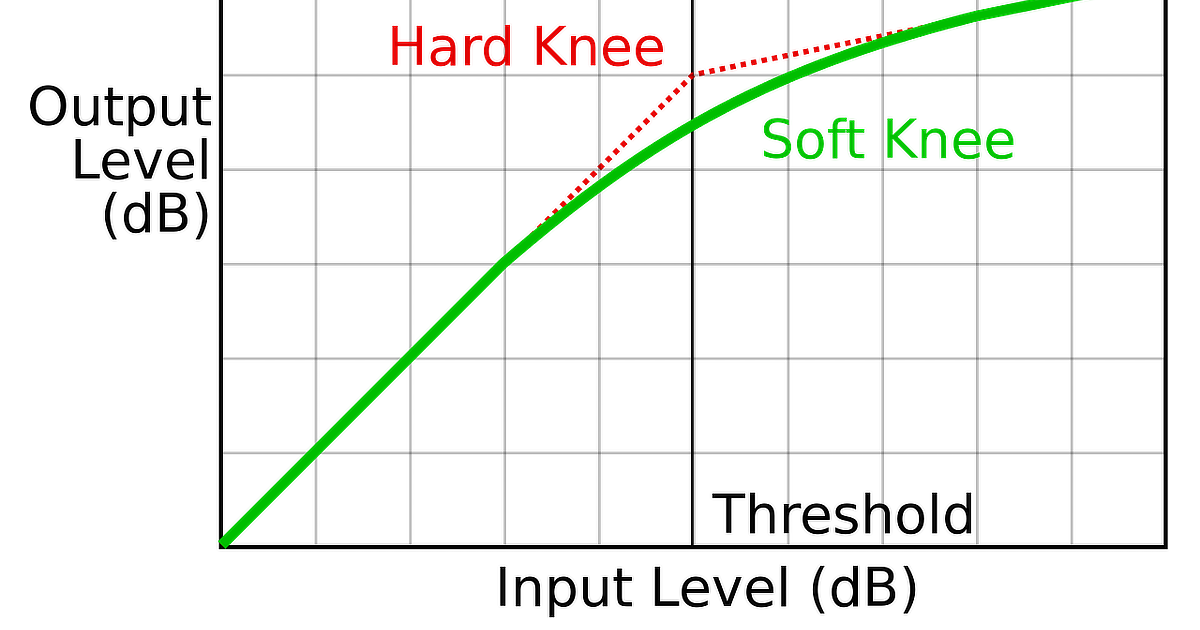

What Is The Knee In Logic Compressor?

In a logic compressor, the knee is the point at which the compressor starts to operate on the incoming signal. It’s the spot where the ratio starts to take effect and signals above the threshold are compressed.

What Is The Knee Width Of A Compressor?

The knee width of a compressor varies depending on the type and model of the compressor. It’s important to check the specifications of the compressor for its specific knee width measurement.

Conclusion

Proper knee setting on a compressor is crucial for efficient and safe operation. By ensuring correct alignment and balance of forces, you can extend the life of your compressor and prevent costly downtime. Take the time to properly adjust your compressor’s knee settings, and don’t forget to regularly inspect and maintain all components.

Remember, a little preventative maintenance goes a long way in ensuring the longevity and reliability of your equipment.